How Good Are Your Brakes?

Two things every motorcycle rider does over and over again – start and stop. It’s easy to focus on engines and transmissions – the go part – because after all nothing is more thrilling than a blast of acceleration. But brakes matter too. Racers often say, “to go fast you need big brakes”. As engine displacement and horsepower increase, likewise the need for bigger brakes.

Absent good brakes we’d never be fast in the twisties. Brakes are the key to marshalling raw power to achieve optimal corner entry speeds and suspension loading. The more aggressively one rides the more sensitive one becomes to the importance of good brakes.

So, do your brakes match the way you ride?

Designed for Purpose

Over the years, motorcycle brakes have become an increasingly complex system of interconnected components. Front and rear brakes are linked by a system of interconnected hydraulic lines. Hydraulic pressure is metered and proportioned by valves that react to rider inputs. ABS systems stand by ready to intercede in the event of skidding. But at the heart of the system, three core components do the hard work. The master cylinder creates hydraulic pressure. That pressure causes brake calipers to compress. And the compression brings brake pads into contact with the brake rotor causing friction which in turn slows and stops the bike.

The fundamental principles are old and well proven, while the components themselves have evolved to keep up with advances in motorcycle performance and suspension. The brake system for any given motorcycle is designed around a combination of the motorcycle’s overall ride characteristics and those of the customer segment for which the motorcycle is intended.

A closer look at the three core components makes this clear and can serve as a first step to the optimal brake set-up.

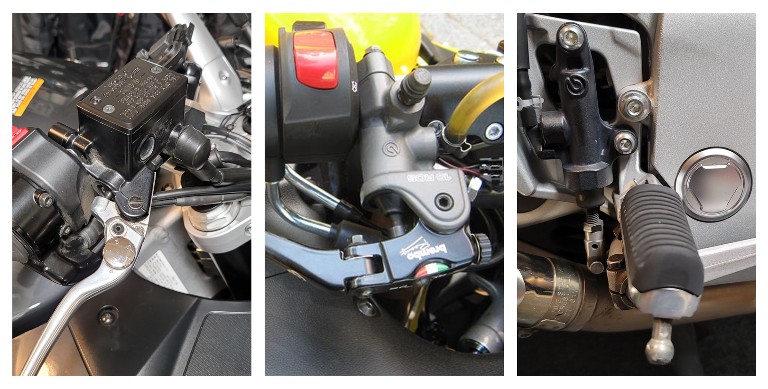

Master Cylinder

The master cylinder is the first of three core brake system components. It’s the element that translates brake lever or pedal pressure to braking power. Every bike has two master cylinders – one on the handlebar operating the front brake and one near the brake pedal for the rear. Each has a brake fluid reservoir as well. Pressing the brake lever or pedal moves a piston in the master cylinder which sends hydraulic pressure through the brake lines to the brake calipers which then press the brake pads against the rotor causing friction and slowing or stopping the bike.

Front brake master cylinders are either radial or axial mounted, which simply means the piston moves through the cylinder in parallel with the lever motion (radial) or orthogonally (axial).

Street bikes typically come equipped with an axial mounted front master cylinder. This design is less costly to manufacture and more forgiving of abrupt rider inputs. On the downside, rider feedback is more muted, and adjustability is limited.

Race bikes, and a few ultra performance street bikes like the Suzuki Hayabusa, use a radial mounted master cylinder. They are more expensive but have the advantage of giving the rider a high degree of feedback, increased braking precision, and full adjustability.

Rear master cylinders are mounted in a radial fashion, that is the piston moves in line with the pedal.

Brake Calipers

Brake calipers use hydraulic pressure to push pistons against brake pads which in turn press against the rotor creating stopping force. Like master cylinders, manufacturers can choose from two calipers designs.

Floating calipers are designed with pistons on only one side of the caliper. When the pistons push one pad against the rotor, the pad on the opposite side pulls in against the rotor as well. This “float” design is less expensive to manufacture and best suited to lower-end motorcycles.

Performance oriented and most heavier motorcycles use fixed calipers. Unlike floating calipers, fixed calipers operate pistons on both sides of the rotor. Fixed calipers are more expensive to manufacture, have more parts to maintain, but offer better brake feel and performance.

A fixed caliper can be made from a single block of metal, or by bolting two halves together. A single block, or monoblock caliper, is more rigid and lighter, but also more expensive to manufacture. MotoGP bikes carry monoblock calipers as do ultra-performance street bikes.

Street bikes rely on both fixed and floating calipers at the rear. The FJR for example uses a single piston floating caliper on the back.

The size and number of pistons within a caliper is worth noting as well. Most OEM calipers use four pistons, two per side, and all having the same diameter. This configuration delivers the highest amount of stopping power. However, some calipers are designed with a small and large diameter piston on each side. The claimed advantage over four equally sized pistons is that the smaller piston will engage before the large one giving the rider better brake feel.

One more thing to consider about brake calipers is how they are mounted to the bike. An axial mounted caliper attaches to the fork or in the case of the rear caliper to the frame with the attachment bolts running at a 90° angle to the brake pads. This method is lower cost but leaves the caliper susceptible to deflection under heavy load. A radial mounted caliper on the other hand uses a bolt pattern that aligns with the rotation of the wheel. The result is greater stability and in the extreme better brake feel. The actual difference in brake performance is unlikely to be noticed except in the most demanding situations. Still, radial mounted calipers are a sure sign the engineering team had a high-performance rider in mind.

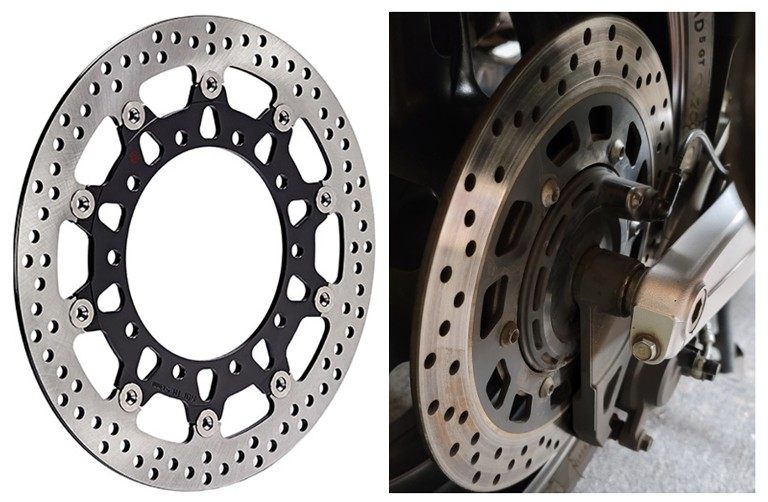

Brake Discs and Pads

The third crucial brake system component is the combination of brake disc and pads. This is literally where the rubber meets the road.

Sport touring bikes are equipped with two-part brake discs. An inner carrier attaches to the wheel axle and an outer disc attaches to the carrier. Brake discs are either floating, semi-floating, or fixed, where the difference is the ability of the disc to move laterally staying in constant alignment with the brake pads. A floating and semi-floating disc is constructed in two parts by attaching an outer disc to an inner carrier using pins. The pins on a floating disc allow the outer disc to move while those on a semi-floating disc do not. In both cases, a two-part disc is less prone to heat-warping and lighter but more expensive to manufacture.

Fixed discs and semi-floating discs do not adjust automatically to worn pads while a fully floating disc will. With no way to self-adjust, a fixed disc system can result in excessive brake drag.

All popular sport touring motorcycles use floating discs up front. Most use a semi-floating disc at the back.

Brake pads are the final link in the chain. They create the friction that stops the bike. At the same time, friction wears down the pad, the disc, and generates a good deal of heat in the process. Excessive heat can cause brakes to fade in two ways. First by reducing the coefficient of friction between the pad and disc; and secondly, by overheating the brake fluid and in so doing changing its properties from non-compressible to compressible.

Two factors are important to keep in mind when choosing brake pads for sport touring where the demands of both sport-style riding and the weight of a larger bike and luggage converge.

First, select pads with an HH SAE rating. These pads are designed to deliver a high coefficient of friction at both low temperature (the first H) as well as at high temperature (the second H). However, like any pad regardless of rating, they create heat. Pads rated HH just handle it better.

Secondly, choose pad material that stands up to heavy use and a range of weather conditions. Sintered pads, meaning ones made from fused metallic particles, are the most popular choice for sport touring. They are durable and perform well in dry and wet conditions alike. Some argue sintered pads are harder on discs, which is true, but the degree of extra wear is not significantly greater than less performant pads and not worth the performance trade-off.

Some riders may opt for ceramic pads when available for their motorcycle make and model. Ceramic pad linings are manufactured from bonded ceramic fibers (and a small amount of metallic fiber). These pads perform similarly to HH rated sintered pads, and manufacturers claim they are easier on rotors, create less dust and less brake noise. But excessive wear and noticeable dust and noise are rarely a problem with sintered pads. None of these benefits are enough to justify the marginal extra cost of ceramic pads for even the most extreme street rider.

Popular sport tourers from manufacturers like BMW, Yamaha, and Suzuki all come equipped with HH rated sintered pads.

The Right Brakes For You

Understanding how brakes operate and in particular the three central brake system components will help guide riders to the best choice for their motorcycle and the way they ride. For the vast majority of sport touring riders, factory installed brake parts far exceed what’s needed for any safe riding situation. That means a margin remains for those times when the road calls for a little more or even the occasional day on the track.

But those who regularly push the envelope hard may want to explore aftermarket upgrade options. Before investing, take a moment to think through what’s driving the need to upgrade and the desired performance benefits. Then talk with a qualified mechanic or directly with one of the leading brake part manufacturers to decide on a strategy. Remember – brakes work as a system. Changing one component will have an effect on the others. Always take a wholistic and balanced approach.

by John DeVitis, Editor and Publisher

John DeVitis, Editor & Publisher of American Sport Touring, has been riding and writing about all things motorcycling for decades, with a special focus on sport touring motorcycles. He possesses an uncanny knack for discovering little-known roads in picturesque locations across the United States and Canada, turning riding adventures into stories that inspire readers to explore. These experiences, both on the road and in digital publishing, including years at MSNBC.com—have shaped strong editorial principles and a clear vision, assuring readers of high-quality content they can trust.

Did we hit the mark?

Tap thumps up or thumbs down to send your comments to the editor.

Your feedback helps improve American Sport Touring. We do not use your information for any other purpose.

Please read our Privacy Policy.